- Production Machines >

- Other Manufacturing Equipment >

- Universal mill

Universal mills

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Rotational speed: 3,000 rpm - 20,000 rpm

Machine width: 300 mm

Machine height: 350 mm

... included in the scope of delivery. MultiDrive universal crusher can perform a wide range of crushing tasks involving coarse and fine crushing, thanks to the variety of vessels available. There is a USB ...

IKA

Rotational speed: 3,000 rpm - 20,000 rpm

Motor power: 1,000 W

Machine width: 300 mm

... steel beater. The plastic milling tube can be autoclaved. This effectively prevents cross-contamination even if it is used multiple times. An integrated RFID chip simultaneously stores and limits the lifespan of the ...

IKA

Rotational speed: 400 rpm - 8,000 rpm

Sound pressure: 50 dB

Machine length: 178 mm

... The package includes the powerful ULTRA-TURRAX® Tube Drive P control homogenizing system, which has been designed for universal use. In combination with the disposable mixing vessels with dissolver disc (DIS-300-S-M ...

IKA

Rotational speed: 300 rpm - 3,000 rpm

Output: 60 kg/h

... you can fine tune the comminution process for each sample within a very wide range of applications. The high-speed Universal Cutting Mill PULVERISETTE 19 with a torque of up to 30 Nm comminutes dry, soft ...

Fritsch GmbH - Milling and Sizing

Rotational speed: 2,000 rpm - 14,000 rpm

Overview Reproducible comminution for a wide range of samples The quietly operating Knife Mill PULVERISETTE 11 is the ideal laboratory mixer in industry quality for very fast and gentle comminution and homogenisation ...

Fritsch GmbH - Milling and Sizing

Rotational speed: 50 rpm - 700 rpm

Output: 60 kg/h

... swift, blockage-free operation and fast cleaning without residue. Running stabilisation due to flywheel mass The Universal Cutting Mill PULVERISETTE 19 is equipped with a flywheel mass to stabilize ...

Fritsch GmbH - Milling and Sizing

Output: 50 kg/h - 1,500 kg/h

LM series granulators are equipped with rotor and stator knives in a crossed manner for scissor like exact cutting action. This machine helps in finer and identical cutting and keeps the heat formation stable. This type of cutting also ...

Final grain size: 100 µm - 100 µm

Output: 60,000 kg/h - 480,000 kg/h

Motor power: 2,200, 4,000, 3,000 W

The Waste water Grinder from United Tech Machinery is a high torque, low rotating speed and double shaft grinder under water. It is designed to pulverizing all kinds of solid waste ( clothing, plastic, trash, wood, aluminum can, glass ...

Output: 60 kg/h - 110 kg/h

• Machine made entirely of AISI 304 stainless steel • Robust construction to increase processing precision and for improved long-term durability • Cutting rollers adjustable up to ± 10 mm gap • Cutting roller speed adjustable via inverter • ...

Output: 1 kg/h - 50,000 kg/h

... the FNG is easy. The Universal mill is equipped with air insufflation at bearing level to eliminate all risk of cross-contamination in the case of multi-product use. The extensive FNG range starts ...

POITTEMILL / FORPLEX

Final grain size: 1 µm - 500 µm

Rotational speed: 12,000 rpm - 18,000 rpm

Output: 5 kg/h

The Universal Laboratory Mill (FNG00) is the smallest crushers of the FNG range. Manufactured in the mass and built steel stainless 316L welded mechanic, it is intended for the small installations of ...

POITTEMILL / FORPLEX

The BRF dual-rotor universal mill is an evolution of the FNG universal mill. The BRF’s design is based on FORPLEX impact crushers (such as the FNG or FPX models) but ...

POITTEMILL / FORPLEX

Motor power: 2.2 kW

The spiral jet mill AS 200 II Baseline is designed to combine a well-known and proven technology with high economic efficiency. The design focuses on basic GMP requirements and standardised modules, realised with high ...

Motor power: 90 kW - 450 kW

Machine weight: 6 t - 31 t

Gentle and fast disintegration of composite materials With the ADuro QZ, ANDRITZ has revolutionized traditional shredding technology. The machine does not use any cutting tools, but breaks up the input material gently and quickly by ...

ANDRITZ Recycling

Output: 2 t/h - 19 t/h

The Hammer Mill, series PHMS is used for the economical preparation of wood chips from round wood, residual wood, waste wood or annual plants. The wood chips are of high quality and can be directly injected for combustion, ...

Output: 500 kg/h

Dec’s Universal Milling System provides the ultimate in flexibility, taking up the minimum area for the maximum product recovery. Its easily accessible interchangeable grinding media mill ...

Final grain size: 1 µm - 5,000 µm

Rotational speed: 800 rpm - 4,000 rpm

Output: 1 t/h - 15 t/h

The universal impact mills type “P IMPACT MILLS TYPE “P – D – PC” are specially used for: • Production of fine powders and sands of limestone and dolomite for glass industries, mortars, ...

Output: 40 t/h - 300 t/h

Motor power: 250, 37 kW

Machine weight: 4,600 kg - 25,000 kg

Impact crushers and impact mills (HSI) are universal and, at the same time, economical solutions. The BHS impact crusher achieves very high crushing ratios in both the first and second stage. This results ...

Motor power: 8, 160 kW

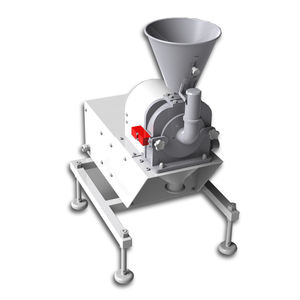

... Bauermeister Universal Mills are built in seven sizes as production machines as well as in one laboratory mill size. Universal Mills owe their name to ...

Bauermeister Zerkleinerungstechnik GmbH

The KEK Universal Mill provides high-energy one-pass fine grinding. Available with a variety of interchangeable grinding media, the KEK Universal Mill is capable of unsurpassed, ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining