- Industrial machines and equipment >

- Mixing and Dosing >

- Volumetric dosing dispenser

Volumetric dosing dispensers

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... The metering time and metering pump size need to be selected correspondingly to be able to meter volumes larger by a factor of 2.8. Depending on the product used, the metering volume ...

ProMinent Group

... on demand and the circulating volume, peristaltic pumps of the DULCOFLEX product range are used. Sensors, controllers and metering pumps form a single perfectly coordinated unit with the chemical tanks, which can reliably ...

ProMinent Group

... the product range DULCOFLEX, alpha type motor-driven metering pumps or beta type solenoid metering pumps are used, depending on demand and the circulation volume. Sensors, controllers and metering ...

ProMinent Group

A semi-automatic dispensing system designed to dispense LOCTITE adhesives and fluids packaged in 10 ml, 30 ml and 55 ml syringes. The unit has digital timing control with decimal settings for increased ...

Henkel LOCTITE

An I4.0-enabled semi-automatic dispensing system designed for precision dispensing of LOCTITE adhesives and fluids packaged in 10 ml, 30 ml and 55 ml syringes. The resistive touch-screen ...

Henkel LOCTITE

Loctite Multiple 300 ml Cartridge Pusher System In addition to the large variety of LOCTITE standard dispensing and curing equipment, Henkel also offers custom-built equipment solutions to suit specific customer needs. ...

Henkel LOCTITE

Continuous metering ensures high process reliability DOPAG developed the eldodis gear metering system specially for the processing of medium to high-viscosity single-component materials. ...

DOPAG - Metering, Mixing and Dispensing Technology

Accuracy: 1 %

Reliable metering with short cycle times Piston metering units are used for processing 1K media, especially when short cycle times are required. All that is required is appropriate material supply ...

DOPAG - Metering, Mixing and Dispensing Technology

... experience in release label coating projects over many years has brought to our attention the pressing need for a comprehensive dosing solution that would target all the unique requirements of this application. The coatingmix ...

DOPAG - Metering, Mixing and Dispensing Technology

... to drive the metering system, delivers an extremely consistent mix/meter of materials at low flow rates, ideal for low & high pressure applications, and more. The MiniLink system uses a hydraulic motor and cylinder ...

... to drive the metering system, delivers an extremely consistent mix/meter of materials at low flow rates, ideal for low & high pressure applications, and more. The MiniLink system uses a hydraulic motor and cylinder ...

Precise, proven metering technology With true 1:1 delivery of Urethane, Epoxy, Silicone or Polyester materials, it is ideal for materials used in coating, adhesives, casting and laminating resins. Features: • Precise, ...

Metering Unit Medium: oil / grease Drive: pneumatic Dosing volume per stroke and outlet in cm³: 0,04...0,28 max. delivery pressure in bar: 85 Number of outlets: 1

... reagent dispensing! The WELLJET reagent dispenser and dispenser stacker offer low cost, fast, and precise bulk dispensing while saving valuable bench space. The cost-efficient and handy ...

... volume. XDOS (Extended dosing) – Controlled dosing Fixed volume dosing: The volume and the dosing rate are specified. Time-controlled dosing: ...

... volume. XDOS (Extended dosing) – Controlled dosing Fixed volume dosing: The volume and the dosing rate are specified. Time-controlled dosing: The ...

Experience a new level of ease with Nordson EFD’s UltimusPlus™ dispensers. Train operators in seconds with intuitive touchscreen control of dispensing parameters. Designed to simplify setup and operation, ...

Nordson EFD

... small as 0.5 nL with extreme precision and repeatability at up to 1000Hz continuous for your most sophisticated non-contact dispensing application needs.

Nordson EFD

NORDSON developed the Ultimus V High Precision Dispenser to provide proper and precise disbursement of fluids that turns viscous over time. Ideal usage will be epoxies and UV cure adhesives. It can also dispense thinner ...

Nordson EFD

SureFoam systems mix hot melt adhesives with inert gas to create a closed-cell foam when dispensed. The adhesive/gas mixture can be applied in a swirl or bead pattern for bonding applications. The foamed material increases manufacturing ...

liquids with chunk dosing dispenserViSCO.series

Accuracy: 1 %

... cleaning are characteristic for this Beinlich pump series. Advantages High dosing accuracy, ± 1% volumetric Continuous dosing independent of viscosity Low shear stress on dosing ...

ViscoTec 1C dispenser vipro-PUMP ▪ Volumetric dispensing, regardless of viscosity ▪ For low to high viscosity materials ▪ Particularly suitable for highly abrasive, filled or shear sensitive materials ▪ ...

ViscoTec Pumpen- u. Dosiertechnik GmbH

ViscoTec 1C dispenser vipro-PUMP MR ▪ Continuous volumetric and pulsation-free dosing regardless of viscosity ▪ For low viscosity and self-levelling materials (e.g. trickle resins) ...

ViscoTec Pumpen- u. Dosiertechnik GmbH

... cycle times ▪ Non-destructive dosing of solid containing materials with diameter of up to 20 mm ▪ Volumetric dosing and filling, regardless of viscosity ▪ For low to high viscosity materials ▪ ...

ViscoTec Pumpen- u. Dosiertechnik GmbH

continuous-flow dosing dispenserCFD mta®

The volumetric continuous flow dispenser (CFD) is a high-precision dispenser based on progressive cavity technology. The CFD was designed to be highly versatile both in material compatibility ...

mta robotics AG

... two-components dispenser The NBD two-components volumetric dispenser can be integrated on most of our standard dispensing platforms including: MRC500, TR300, OEM, ...

mta robotics AG

... mono-component dispenser The NVD mono-component volumetric dispenser can be integrated on most of our standard dispensing platforms including: MRC500, TR300, OEM, ...

mta robotics AG

volumetric dosing dispensereco-PEN300

... Your advantages: - Genuine volumetric dosing - Suck back effect - Viscosity independent dosing - Easy to clean - Primary pressure-independent dosing - Controllable ...

preeflow by ViscoTec Pumpen- u. Dosiertechnik GmbH

... with maximum volumetric precision - dot-and-bead application with application speeds adaptable to track speeds - joint sealing technology Your advantages: - Genuine volumetric dosing ...

preeflow by ViscoTec Pumpen- u. Dosiertechnik GmbH

... with maximum volumetric precision - dot-and-bead application with application speeds adaptable to track speeds - joint sealing technology Your advantages: - Genuine volumetric dosing ...

preeflow by ViscoTec Pumpen- u. Dosiertechnik GmbH

ThePen by START International is a refillable pen for controlled application of liquid solutions. It can be filled with many different kinds of liquids (fluxes, alcohol, protective coatings, lubricating oil, inks, etc.). The fine tip ...

SPECTROFLEX G is ideally suited for dosing powders, pellets, regrind, granulate, flakes and fibers in continuous processes. motan's unique interchangeable system provides two huge advantages over common dosing ...

Progressive metering elements with steel body, hardened piston, high pressure sealing ring, device for connecting or separating the outlets. Specifications: - Working pressure max 400 bar (5700 psi) min 20 bar (290 ...

... Gravimetric (in g) or volumetric (in ml) dosage is equally possible with the AutoDosage system. A maximum of 70 different dosage or dilution programs can be set and stored on the device. Applications The SCHMIDT ...

Flow rate: 0.5 kg/h - 350 kg/h

... of the dosing roller is filled evenly before it is discharged. The constant speed guarantees high dosing accuracy. Type Kö - Grain station for masterbatch (type Kö 2 to Kö 4) Save color by chamber ...

Koch-Technik, Werner Koch Maschinentechnik GmbH

Flow rate: 0.5 kg/h - 15 kg/h

... color shades when coloring. Volumetric dosing of powder Chamber volume dosing via a dosing roller is an uncomplicated solution for the precise dosing ...

Koch-Technik, Werner Koch Maschinentechnik GmbH

Flow rate: 7 kg/h - 200 kg/h

Dosing of new material (semolina and grains) or regrind Precise volumetric dosing of large quantities via a cellular wheel Volumetric dosing stations ...

Koch-Technik, Werner Koch Maschinentechnik GmbH

high-viscosity media dosing dispenserNEMO®

... rejects and unnecessary costs. Furthermore, the dispensers and manual dispensers impress with their compact design and valve-free dosing method. This prevents increased downtimes and ...

Power: 20 kW - 65 kW

... offering the highest quality in all its decisive elements. The HIGHLINE MK2 provides a seamless transition to a high-performance metering machine, and can be used for processing virtually all raw material systems. The ...

Hennecke GROUP

Power: 28 kW - 45 kW

Next generation high-pressure metering machines for a wide range of standard applications The ECOPLUS MK2 is the first model from Hennecke's new 'NEXT-GEN metering machines' and has been completely ...

Hennecke GROUP

Power: 33 kW - 56 kW

High-pressure metering machines for HP-RTM, clearmelt and CLEARRIM applications STREAMLINE metering machines come equipped with comprehensive standard parts, a self-cleaning high-pressure mixhead and ...

Hennecke GROUP

SDA: Smart Dosing Applicator Volumetric applicator and controller PRECISION AND AGILITY SDA has a gear pump installed in the applicator body to ensure maximum precision when applying the adhesive. ...

... Therefore the dispensing machine dispenseALL 420 offers a lot of options for every application. 1 up to 3 dispensing valves time-pressure valves precision dispenser ...

... possibility of dispensing like the LM901 but not the pick and place function. Options like the X-Y locking or a camera enables the efficient dispensing of prototypes and complete series. For applications ...

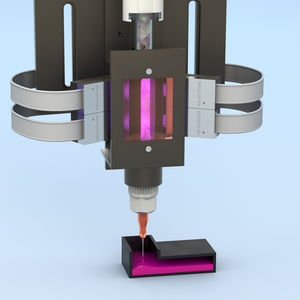

volumetric dosing dispenserDELO-ACTIVIS 600

DELO-Activis 600 is a volumetric dispenser for adhesives Your benefits at a glance: Less CO2 emissions, process costs reduced by more than 50 % and maximum design freedom In addition to mechanical ...

Accuracy: min 99.0 %

High-precision adhesive dispensing for series production of electronic components The volumetric one-component dispensing system applies the smallest adhesive quantities ...

Flow rate: 480 kg/h

Device enabling single dispensing using gravity, with electronic metering and automatic stoppage of water volume without control of process water temperature. The DMG Box water meter is only suitable ...

Flow rate: 900 kg/h

Device enabling single dispensing, with electronic metering and automatic stoppage of water volume without control of process water temperature. Dispenser requiring mains network water pressure or ...

GP + Cartridges + Needle Valve + Controller Volumetric dispensing of: Silicone and MS sealants, High or very high viscosity adhesives or lubricants. Dispensing of medium and high ...

DAV TECH Srl

PP50 + GP + Needle valve + Controller Volumetric dispensing system for medium-high viscosity fluids contained in drums from 5 to 200 liters. Dispensing of medium ...

DAV TECH Srl

PDP + Cartridges + Controller Volumetric dispensing system: maximum precision and repeatability for dispensing of Gapfillers and Thermo-conductive Pastes. Dispensing ...

DAV TECH Srl

Your suggestions for improvement:

A volumetric feeder is used to measure different materials by volume.

ApplicationsThese devices are often used to dispense liquids, but can also handle flowing solids and various types of bulk materials. Precision and volume adjustment vary with operational specifics.

TechnologiesSolids are dispensed by a device equipped with a feed screw, an agitator, a vibrator or another mechanism. When handling liquids, a measuring chamber or a feed pump is employed.

How to chooseChoice will depend on the material to be handled. This may be a powder, granules or another solid, a liquid in resin or paste form, or a gas. Other important factors are the quantity of product and the required degree of accuracy.

- Rapid dispensing

- Can deliver several components at the same time

- Reduced accuracy

- Liquids and gases require constant temperature

- Difficult to adjust batch size

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining