- Hydraulics - Pneumatics

- Valve

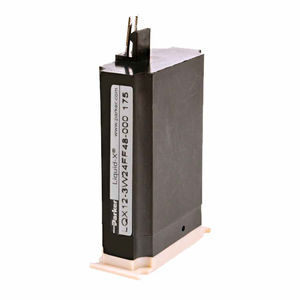

- Direct-operated solenoid valve

- Parker Precision fluidics Division

- Products

- Catalogs

- News & Trends

- Exhibitions

Direct-operated solenoid valve DS series2-waynormally opennormally closed

Add to favorites

Compare this product

Characteristics

- Control

- direct-operated

- Ports/positions

- 2-way

- Function

- normally closed, normally open

- Medium

- hydraulic

- Body

- seat

- Other characteristics

- cartridge, spring, unloading, load

- DN

Min.: 11 mm

(0.433 in)Max.: 260 mm

(10.236 in)- Voltage

2 V

- Temperature

Min.: -35 °C

(-31 °F)Max.: 204 °C

(399 °F)- Pressure

250 bar

(3,625.9 psi)

Description

Parker's 2-way poppet solenoid valves check flow in one direction with very low leakage and free flow opposite; normally-open or normally-closed configurations available. Capable of pressures up to 350 bar (5000 psi) and flows up to 260 lpm (70 gpm).

Parker’s 2-way poppet style solenoid valves feature a proven design that ensures very low leakage when flow is blocked in one direction and minimized pressure drop in the free flow position. These valves can operate with hydraulic system flows as high as 260 lpm and pressures up to 350 bar with normally-open or normally closed configurations available. Parker’s 2-way poppet solenoid valves are ideal for unloading and load holding applications that require low poppet style leakage within mobile, industrial, or manufacturing markets.

If the nose of the cartridge (port 1) is pressurized enough to overcome the spring force, and pushing the poppet off of its seat, flow will be allowed through port 1 to port 2. When the coil is energized, the pilot poppet is lifted off of its seat, venting the pressure inside the poppet to port 1. This creates a pressure imbalance across the main poppet, therefore lifting the poppet and allowing flow from the side to the nose (2 to 1). Because these valves are pilot operated, a minimal amount of pressure differential is necessary (25-50 psi), along with flow between ports 2 and 1 must be present to overcome the spring and lift the poppet.

The normally open valve pilot is held off its seat by spring force. Pilot flow is vented to port 1, creating a pressure imbalance that moves the main poppet. This differential lifts the poppet allowing flow from the side to nose (2 to 1).

Catalogs

No catalogs are available for this product.

See all of Parker Precision fluidics Division‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other Parker Precision fluidics Division products

VALVES

Related Searches

- Valve

- Control valve

- Electrically operated valve

- Flap valve

- Non-return valve

- Gas solenoid valve

- ISO valve

- Normally closed solenoid valve

- 2-way solenoid valve

- Pressure limiter

- Direct-operated solenoid valve

- Single-stage regulator

- Valve for industrial applications

- Metal solenoid valve

- Industrial regulator

- Hydraulic valve

- 2-way valve

- Cast valve

- Air solenoid valve

- Diaphragm pressure regulator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.