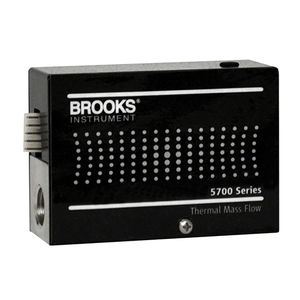

Thermal mass flow meter SLAMf seriesfor gasstainless steelRS485

Add to favorites

Compare this product

Characteristics

- Technology

- thermal mass

- Fluid

- for gas

- Material

- stainless steel

- Communication

- 4-20 mA, RS485, PROFIBUS

- Protection level

- IP66, NEMA 4X

- Applications

- industrial, for harsh environments

- Other characteristics

- digital, high-accuracy, electronic, programmable, with mass flow controller

- Volumetric flow rate

Max.: 36,000 l/min

(9,510.2 us gal/min)Min.: 0 l/min

(0 us gal/min)- Process temperature

Max.: 65 °C

(149 °F)Min.: -14 °C

(7 °F)- Process pressure

70 bar, 100 bar, 310 bar

(1,015.26 psi, 1,450.38 psi, 4,496.17 psi)- Precision

0.18 %, 0.9 %, 1 %

- Repeatibility

0.2 %, 0.25 %

Description

Precision mass flow control. Hardened for the harshest environments. Now available with EtherNet/IP™

Whether it’s dust, moisture, temperature extremes or wash-down requirements, the SLAMf Series elastomer sealed thermal mass flow controllers and meters deliver the precise accuracy and long-term stability of our proven SLA5800 family of meters and controllers. A specially engineered NEMA4X/IP66 enclosure protects our advanced digital electronics and ensures stable, accurate measurement and control of your process-critical gas mass flows.

Features

• ISO/IEC 17025 accredited

• SLA Series Biotech MFC offers two options packages with features created specifically to improve bioprocessing performance

• NEMA4X / IP66 rated hardened enclosure

• Suitable for a broad range of temperature and pressure conditions

• Industry-leading thermal flow measurement sensor technology delivers excellent accuracy

• Broad array of available communication options includes the EtherNet/IP™ protocol which features a web-based interface that lets you easily configure network settings

• Programmable multi-gas/multi-range capabilities

• Advanced self-test routines and an independent diagnostic service port lets users troubleshoot or change flow conditions without removing the MFC from service

Benefits

Hardened device housing ensures process accuracy and control in harsh conditions

Proprietary thermal sensing technology delivers superior signal to noise ratio at low set points

Long-term sensor stability reduces maintenance and periodic recalibration requirements

Choose one device, program up to six different gas calibrations

VIDEO

Catalogs

SLAMf Series

12 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Brooks instruments flow meter

- Liquid flowmeter

- Pressure transmitter

- Pressure gauge

- Analog pressure transmitter

- Brooks instruments gas flow meter

- Brooks instruments stainless steel flow meter

- Analog pressure indicator

- Pressure switch

- Waterproof flowmeter

- Industrial flowmeter

- Membrane pressure transmitter

- Stainless steel pressure transmitter

- In-line flowmeter

- Precision flowmeter

- Compact flowmeter

- Threaded pressure gauge

- Water flowmeter

- Stainless steel pressure indicator

- Digital pressure transmitter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.