- Hydraulics - Pneumatics

- Pump

- Crude oil pump

- KRACHT GmbH

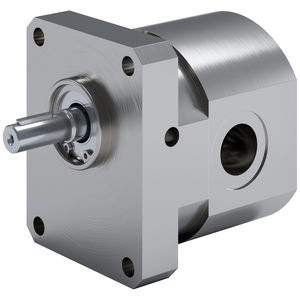

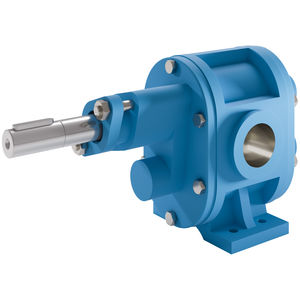

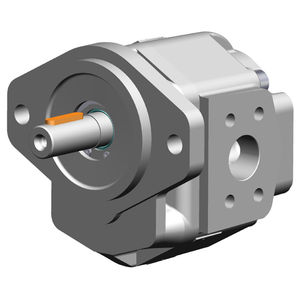

Solvent pump KF 730...1500for coolantfor crude oilfor polyurethane

Add to favorites

Compare this product

Characteristics

- Fluid

- for solvents, for coolant, for crude oil, for polyurethane, for lubricants

- Priming

- self-priming

- Technology

- external-gear

- Domain

- industrial, for the chemical industry, for the mining industry, for the petrochemical industry, for the metallurgical industry, for the paper industry, for the textile industry, for maritime applications

- Material

- cast iron, steel

- Other characteristics

- modular, low-noise, combined, seal

- Flow

Min.: 486 l/min

(128.38762 us gal/min)Max.: 2,568 l/min

(678.39383 us gal/min)- Pressure

Min.: 0 bar

(0 psi)Max.: 25 bar

(362.594 psi)- Fluid temperature

Min.: -20 °C

(-4 °F)Max.: 200 °C

(392 °F)

Description

Gear pumps KF are used for pumping a wide variety of fluids. Gear pumps KF are distinguished especially by their wide range of variants which are assembled as required on the modular principle and also permit subsequent upgrade.

The standard housing sections are of grey cast iron. The gear units are manufactured from high-strength case-hardening steel, hardened and mounted in special multi-compound plain bearing bushes. The standard drive shaft is sealed by single radial lip-type seal.

All pump sizes incorporate helical tooth system. This feature, combined with special gear geometry, results in extremely low noise levels and reduced pressure pulsation.

Catalogs

No catalogs are available for this product.

See all of KRACHT GmbH‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Chemical pump

- Self-priming pump

- Stainless steel pump

- Lubricant pump

- Transfer pump

- Chemistry pump

- Lubricating oil pump

- Metering pump

- Cast iron pump

- ATEX pump

- Process pump

- High-pressure pump

- Pump for oil industry applications

- Circulation pump

- Steel pump

- Gear pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.