- Machine-tools

- Machining Center

- 5-axis machining center

- Multiax International CNC srl

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

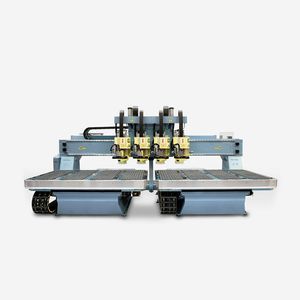

Floor type CNC machining center L series5-axis6-axisswiveling-spindle

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis, 6-axis

- Spindle orientation

- swiveling-spindle

- Structure

- mobile gantry, floor type

- Machined material

- for aluminum, for copper, for non-ferrous metals, for brass, for composites, for wood, for plastics, for ceramics

- Spindle mount

- HSK A-63, HSK F63

- Number of tool stations

- 24 tools, 32 outils, 16 tools, 8 tools

- Applications

- cutting, drilling, for large-diameter parts, for the automobile industry, for the aeronautical industry, for molds, for large workpieces, for the mold industry, for the aluminum industry, for aeronautics, for drilling, for heavy-duty machining, for the plastics industry, foam

- Other characteristics

- high-precision, high-speed, direct-drive, modular, two-station, wet, CE, with pallet changer, tilting-head, wide, chamfering, conveyor belt, with control panel

- X travel

Min.: 2,400 mm

(94 in)Max.: 9,500 mm

(374 in)- Y travel

Min.: 2,500 mm

(98 in)Max.: 42,000 mm

(1,654 in)- Z travel

Min.: 1,200 mm

(47 in)Max.: 4,000 mm

(157 in)- Rotational speed

Min.: 18,000 rpm

(113,097 rad.min-1)Max.: 24,000 rpm

(150,796 rad.min-1)- Power

Min.: 10 kW

(13.6 hp)Max.: 42 kW

(57.1 hp)- Workpiece max height

Min.: 1 mm

(0 in)Max.: 3,000 mm

(118 in)- Work feed X-axis

Min.: 30,000 mm/min

(20 in/s)Max.: 60,000 mm/min

(39 in/s)- Work feed Y-axis

Min.: 50,000 mm/min

(33 in/s)Max.: 60,000 mm/min

(39 in/s)- Work feed Z-axis

Min.: 30,000 mm/min

(20 in/s)Max.: 40,000 mm/min

(26 in/s)- Positioning accuracy

Min.: 25 µm

Max.: 50 µm

- Repeatability

Min.: 12 µm

Max.: 40 µm

- Tool-changing time

Min.: 8 s

Max.: 16 s

- Weight

Min.: 10,000 kg

(22,046.23 lb)Max.: 30,000 kg

(66,138.68 lb)

Description

Floor rails moving gantries. The modular design of the L series makes it precisely addressed to industries requiring a large work envelop along with a high degree of precision such as machining moulds for the automotive, wind energy and marine industry

Heavy duty low rail gantries, ideal for hybrid configurations. One of the most important aspects of an open structure/low rail structure is that it enables maximum accessibility (loading/unloading) either from the front or from the sides. The travelling column design provides an easily accessible ground-level room for crane or forklift truck loading and unloading. Beyond this, the workpiece can be visualized from different perspectives (this is not possible with suspended gantry structures), for being eventually machined again, without being taken out from the machine. This is very useful to prototype departments or any application where the design of the part must be validated before downloading the mould from the CNC machine.

Catalogs

L Series

2 Pages

Other Multiax International CNC srl products

OUR MACHINES

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- Cutting CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- Drilling CNC machining center

- 24 tools CNC machining center

- Compact CNC machining center

- Machining center for the automobile industry

- Direct-drive CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.