- Hydraulics - Pneumatics

- Pump

- Gasoline pump

- Shanghai Weihu Pump Industry

- Products

- Catalogs

- News & Trends

- Exhibitions

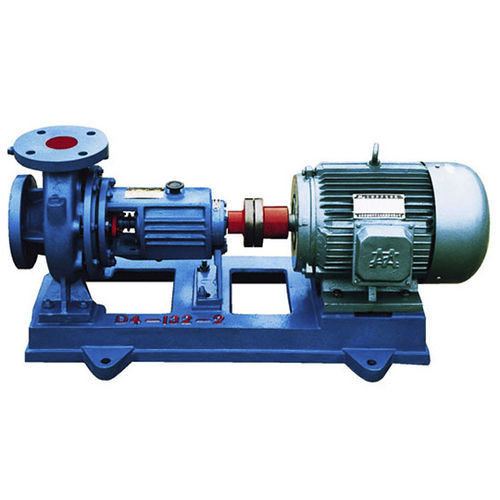

Water pump I seriesoilgasolinediesel

Add to favorites

Compare this product

Characteristics

- Fluid

- water, oil, gasoline

- Operation

- diesel

- Technology

- centrifugal

- Mobility

- stationary

- Domain

- industrial, chemical

- Applications

- circulation, irrigation, drainage, outlet, boiler

- Other characteristics

- suction, mechanical, standard, single-stage, seal, heating

- Flow

Max.: 600 m³/h

(21,188.80003 ft³/h)Min.: 10 m³/h

(353.14667 ft³/h)

Description

IS, ISR, IY series single stage single suction cantilever type centrifugal pump is used to deliver clean water and liquids with similar chemical and physical properties as water but containing no solid particles. This series of pump is the first batch of pumps in China pump industry NEWLY designed according to international standard ISO2858. It has such features as wide range of parameters, high efficiency, good reliability, simple structure, easy to use and maintain, etc. It is chosen and promoted by Chinese government as energy saving product.

Product usage

IS type single stage single suction clean water centrifugal pump can deliver liquids with highest temperature at 80℃. The allowable pressure at inlet is 0.6MPa. It is suitable for water supply and water drainage in factories, mines, urban areas and farm irrigation, etc.

ISR single stage single suction hot water circulation pump can be used for pressurized water circulation supply in energy industry, metallurgical industry, chemical industry, bath room, boiler, city heating system. It can pump liquids with temperature as high as 130℃.

IY single stage single suction light oil pump is used to deliver gasoline, kerosene, diesel and other petroleum products.

Product features

(1)This series of pumps are installed horizontally, suspension type. The liquids is drawn in along horizontal shaft, drained out radially. Its body and cover are divided at its back. You don’t have to disassemble the pipeline as inlet and outlet when taking maintenance. You only need to take down the shaft coupling, withdraw the rotor components before maintenance.

(2) Two kinds of shaft sealing, soft packing seal and mechanical sealing.

Other Shanghai Weihu Pump Industry products

Pipeline Water Pump

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Clear water pump

- Centrifugal pump

- Chemical pump

- Stainless steel pump

- Lubricant pump

- Transfer pump

- Chemistry pump

- Submersible pump

- Compact pump

- Lubricating oil pump

- Suction pump

- Impeller pump

- Mechanically-actuated pump

- Flow pump

- Top-mounted pump

- Discharge pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.