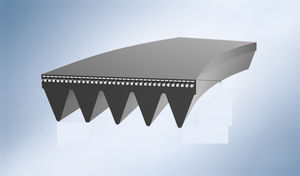

Synchronous belt GT3 seriestimingrubberpositioning

Add to favorites

Compare this product

Characteristics

- Type

- synchronous, timing

- Material

- rubber

- Product applications

- positioning

- Sector

- industrial

- Other characteristics

- low-noise, high-performance

- Length

Min.: 76 mm

(2.99 in)Max.: 2,440 mm

(96.06 in)- Width

Min.: 3 mm

(0.118 in)Max.: 25 mm

(0.984 in)- Pitch

2 mm, 3 mm, 5 mm

(0.079 in, 0.118 in, 0.197 in)- Temperature

Min.: -25 °C

(-13 °F)Max.: 100 °C

(212 °F)

Description

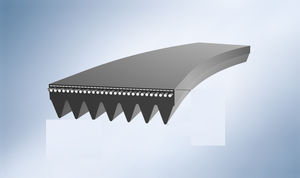

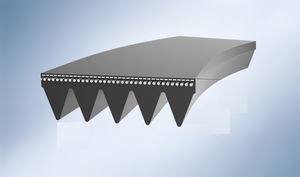

POWERGRIP GT3 NEOPRENE TIMING BELTS

THE PROBLEM SOLVER FOR ALMOST EVERY INDUSTRY

Technical features:

Divisions: 2, 3, 5

Tensile member made of fibre glass

Benefits to you at a glance:

Available around the world

Extremely high-performing due to optimised tooth form and fibre-reinforced rubber mix

Lubrication not necessary

High positioning precision

Can be used with fixed axis spacing

Improved tooth-skipping behaviour

Low-noise running

Compared with previous drive belts and chain drives, timing belts made of neoprene offer a considerably better transfer capacity and better accuracy with a longer service life.

The PowerGrip® GT3 synchronous belt also transfers up to 30% more capacity than any other neoprene-timing belt and, thanks to its outstanding strength, is the optimum drive element for applications at high rotation speeds.

The current generation of belts offers you a high-performance belt with improved tooth-skipping behaviour with lowered noise development.

PowerGrip® GT3 drive belts in the divisions 8 and 14 are electrically conductive as per ISO 9563, which means that they can also be used in areas at risk of explosion. Furthermore, the drive belt works without problems on fixed axial spacing without elongation and with a long service life.

The PowerGrip® GT3 synchronous belt was designed for use in an existing timing belt drive, which means that it can replace the previously used PowerGrip® HTD and GT 2 timing belts without problems and without the need to make adjustments to the system. In the case of new developments, the entire drive train can be optimised by a special tooth system on the timing belt pulleys in order to fulfil your specific requirements.

Catalogs

No catalogs are available for this product.

See all of Walther Flender‘s catalogsRelated Searches

- Gearbox

- Planetary gearbox

- Coaxial gearbox

- Power transmission belt

- Flexible shaft coupling

- Gear train gearbox

- Compact gearbox

- Shafts coupling

- Shaft gearbox

- Helical gearbox

- Transmission gearbox

- Low-noise gearbox

- Bevel gearbox

- Industrial power transmission belt

- Multi-stage gearbox

- Two-stage gearbox

- Torque shaft coupling

- Rubber power transmission belt

- Industrial gearbox

- Flange gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.