Synchronous belt HTD timingrubberpulley

Add to favorites

Compare this product

Characteristics

- Type

- synchronous, timing

- Material

- rubber

- Product applications

- pulley

- Sector

- industrial

- Other characteristics

- double-sided, heat-resistant, profiled

- Length

Min.: 105 mm

(4.13 in)Max.: 4,578 mm

(180.24 in)- Width

Min.: 6 mm

(0.236 in)Max.: 115 mm

(4.528 in)- Pitch

Min.: 3 mm

(0.118 in)Max.: 14 mm

(0.551 in)- Temperature

Min.: -25 °C

(-13 °F)Max.: 100 °C

(212 °F)

Description

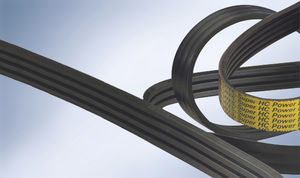

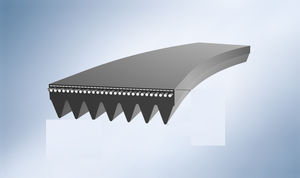

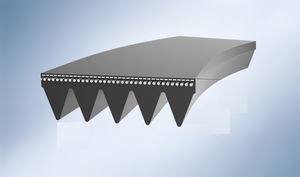

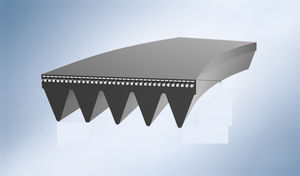

CLASSIC NEOPRENE TIMING BELTS (HTD PROFIL)

THE WALTHER FLENDER SOLUTION FOR THE MEDIUM TO LOWER POWER RANGE

Technical Features:

Divisions: 2, 3, 5, 8, 14, 20

Tensile member made of fiber glass

Benefits to you at a glance:

Replacement parts available around the world

Improvement to internal stress Distribution

High degree of economy

Good flexural properties and low stretching

High Efficiency

Constant angular Velocity

Neither lubrication nor retightening required

Industry-specificv designs

Silicone-free design

Non-standard widths

Cold-resistant designs

Oil- and heat-resistant designs

Electrically conducting designs

Double-sided belts

Grounded backing

Profiled backing

Special tension members

Private Brand Labeling

Concepts for fixed (not-adjustable) centre distances

An optimum belt selection can never be made across the board; it must be based on the individual requirements of the application in question. If a specific drive belt that is adapted perfectly to the timing belt pulley is selected, the efficiency of both the timing belt drive and the entire drive train is improved. Our application technicians will be happy to advise you in the selection of the right synchronous belt for your requirements. Just come and talk to us!

Catalogs

timing belts neoprenes

108 Pages

Related Searches

- Gearbox

- Planetary gearbox

- Coaxial gearbox

- Power transmission belt

- Flexible shaft coupling

- Gear train gearbox

- Compact gearbox

- Shafts coupling

- Shaft gearbox

- Helical gearbox

- Transmission gearbox

- Low-noise gearbox

- Bevel gearbox

- Industrial power transmission belt

- Multi-stage gearbox

- Two-stage gearbox

- Torque shaft coupling

- Rubber power transmission belt

- Industrial gearbox

- Flange gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.