- Packing - Handling - Logistics

- Packing and Packaging

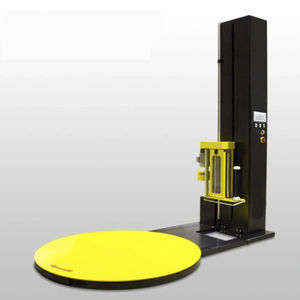

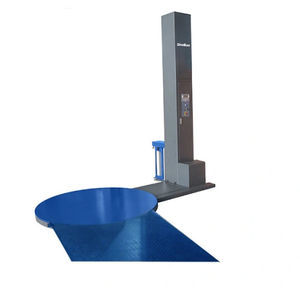

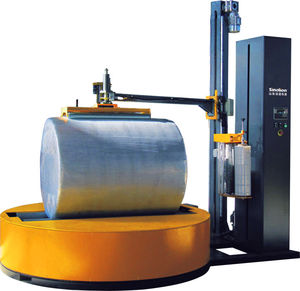

- Turntable stretch wrapper

- SHANDONG SINOLION MACHINERY CORP LTD

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Turntable wrapping machine T1800FZ-PLfully-automaticfor waterfor food products

Add to favorites

Compare this product

Characteristics

- Type

- turntable

- Operating mode

- fully-automatic

- Product applications

- pallet, for food products, beverage, for the electronics industry, for beer, for water

- Other characteristics

- stretch film

- Maximum wrapping height

1,800 mm, 2,200 mm, 2,400 mm, 2,800 mm

(70.87 in, 86.61 in, 94.49 in, 110.24 in)- Maximum pallet length

Max.: 1,200 mm

(47.24 in)Min.: 500 mm

(19.69 in)- Maximum pallet width

Max.: 1,200 mm

(47.24 in)Min.: 500 mm

(19.69 in)- Maximum pallet weight

1,500 kg, 2,000 kg

(3,306.93 lb, 4,409.25 lb)- Table diameter

1,650 mm, 1,800 mm, 2,000 mm, 2,200 mm

(64.96 in, 70.87 in, 78.74 in, 86.61 in)- Rotational speed

Max.: 15 rpm

(94 rad.min-1)Min.: 0 rpm

(0 rad.min-1)- Voltage

380 V

- Power

2 kW

(2.72 hp)- Capacity

Max.: 40 p/h

Min.: 20 p/h

Description

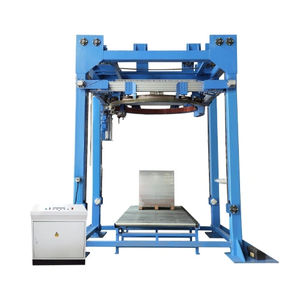

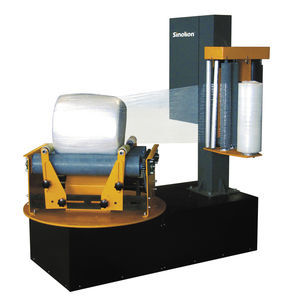

Turntable on-line Pallet Wrapping Machine-T1800FZ-PL full automatic pre-Stretch Wrapping Machine -special film packaging machine.

The packaging machine is used in many kinds of packaging areas widely.

Pallet packaging machine is used to wrap stretch film around the loaded pallets. Stretch Film will provide good protection when the products are being transported& storage. Stretch wrapper is used in beverage and water industry, electronic industry, beer and foodstuff etc.

• Powered pre-stretch system up 300% or 250% to min film consumption(Pre-stretch ratio can be specially made )

• Carriage door opens for effortless roll change and thread film

• Film delivery variable speed by separate AC Drive Motor.

• Heavy duty double-chain carriage lift, calm and safety.

Film clamp& cutting unit:

When stretch wrapping finish, the film will be cut and clamped automatically.

When the film tail is released from the clamp, the air shooter will blow the film tail up, then the film tail will be wrapped by stretch film and keep it tightly with the pallet to ensure no film tail produced.

Film hot melt cutting adopts electrical heating wire to cut the film.

After film being cut, the hot sealer will seal the film tail automatically to ensure no film tail come out.

VIDEO

Other SHANDONG SINOLION MACHINERY CORP LTD products

Wrapping machine

Related Searches

- Packing machine

- Automatic packing machine

- SINOLION stretch wrapper

- SINOLION automatic stretch wrapper

- Packing machine for the food industry

- SINOLION stretch film stretch wrapper

- SINOLION strapping machine

- SINOLION pallet stretch wrapper

- Palletizer

- SINOLION automatic strapping machine

- SINOLION turntable stretch wrapper

- Sealer

- Roll foil

- Case sealer

- Automatic palletizer

- SINOLION semi-automatic stretch wrapper

- Layer palletizer

- Medical packing machine

- Adhesive tape case sealer

- Multi-flap case sealer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.