- Machine-tools >

- Machining Center >

- Precision machining center >

- Mazak

Mazak precision machining centers

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

X travel: 310, 610 mm

Y travel: 250 mm - 1,060 mm

Z travel: 120 mm

... 11 in spindle nozzle Available with automatic tool change. Very high frequency spindle for machining and fine works. Parts held by vacuum table (option). ISO programming, industry standard. Machining ...

Rotational speed: 60,000 rpm

Power: 500, 980 W

... by 500 or 980 W spindle - 60,000 rpm and brushless servomotors. Flexibility and precision of machining with angulation of the rotary axes. 5th axis: 0 to 180 °. Precision by quality ...

X travel: 2,100 mm

Y travel: 1,480 mm

Z travel: 750 mm

... 5 axes milling equipments features transmission by ball screws on the 4 Cartesian axes. Positioning is enabled by the vacuum technology through the use of turbines with side canal or vacuum pump. They offer high-quality ...

X travel: 1,300 mm

Y travel: 720 mm

Z travel: 700 mm

... components guarantee the consistently high precision even in multi-shift production. Thanks to a wide range of accessories, the machining centers become a tailor-made complete solution ...

Knuth Machine Tools

X travel: 1,400 mm

Y travel: 720 mm

Z travel: 700 mm

... components guarantee the consistently high precision even in multi-shift production. Thanks to a wide range of accessories, the machining centers become a tailor-made complete solution ...

Knuth Machine Tools

X travel: 1,000 mm

Y travel: 550 mm

Z travel: 550 mm

The X.mill T series is the newest generation of our vertical machining centers, with modern high-performance compact CNC controls. Whether equipped with Siemens or Fanuc controls, this series offers an ...

Knuth Machine Tools

Breton Ultrix is the monobloc high speed and power vertical gantry milling centre for machining workpieces in superalloys, steel, lightweight alloys or composites

Breton SpA | Advanced technologies and materials

Breton Ultrix is the monobloc high speed and power vertical gantry milling centre for machining workpieces in superalloys, steel, lightweight alloys or composites

Breton SpA | Advanced technologies and materials

Breton Flymill is the 5-axis high speed and power vertical gantry milling centre for machining workpieces in tough materials, steel, or lightweight alloy

Breton SpA | Advanced technologies and materials

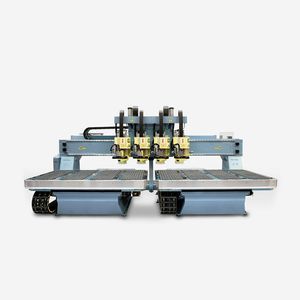

X travel: 7,160, 4,160, 7,000, 4,000 mm

Y travel: 300, 250 mm

Z travel: 250, 270 mm

... optimization of tool lubrication flow direction. The following functions can also be activated: “machining with 4 interpolating axes” (3D Custom Milling Module), “multi-piece machining”, ...

Fom Industrie Aluminium Working Machinery

X travel: 4,160, 4,000 mm

Rotational speed: 20,000 rpm

Power: 7 kW

... automatic adjustment and optimization of tool lubrication flow direction. The following functions can also be activated: ”machining with 4 interpolating axes” (3D Custom Milling Module), ...

Fom Industrie Aluminium Working Machinery

X travel: 4,150, 6,780 mm

Y travel: 545, 440 mm

Z travel: 295 mm

... pneumatic 0°/90°/180° positioning of the electrospindle The ARGO machining centre with 3 controlled axes and pneumatic rotation of the machining head has been designed to carry out drilling and milling ...

Fom Industrie Aluminium Working Machinery

X travel: 762 mm

Y travel: 508 mm

Z travel: 508 mm

5-axis machining is an effective means to reduce setups and increase accuracy for multi-sided and complex parts. The Haas UMC Series universal machining centers are cost-effective solutions ...

Haas Automation

X travel: 1,016 mm

Y travel: 635 mm

Z travel: 635 mm

5-axis machining is an effective means to reduce setups and increase accuracy for multi-sided and complex parts. The larger travels and bigger platter of the Haas UMC-1000 Series Universal Machining Centers ...

Haas Automation

X travel: 1,270 mm

Y travel: 762 mm

Z travel: 711 mm

5-axis machining is an effective means to reduce setups and increase accuracy for multi-sided and complex parts. The larger travels and bigger platter of the Haas UMC-1000 Series Universal Machining Centers ...

Haas Automation

X travel: 550 mm

Y travel: 460 mm

Z travel: 450 mm

HIGHLIGHTS / 5-sided machining in a single set-up / Top thermostability / Swivel range B axis ±100° / Top machining precision / Modern moving column concept / Massive tilting rotary table ...

EMCO GmbH

X travel: 800 mm

Y travel: 610 mm

Z travel: 500 mm

... price-performance ratio / Made in the Heart of Europe EQUIPMENT / Vertical machining center for 4+1-axis machining / Mechanical or Motor Spindle / Tool changer with ...

EMCO GmbH

X travel: 4,550 mm

Y travel: 3,000 mm - 4,000 mm

Z travel: 1,500, 2,000, 2,500 mm

... rack and pinion system / Ram completely guarded / Spindle motor: 60 kW 600 Nm (S1) / Mechanical milling heads 3+2 or 5 axes: 38 kW, 1000 Nm, 6000 rpm / Milling heads with high-speed spindles 5 axes: 42 ...

EMCO GmbH

Weight: 6,500 kg

Overall width: 1,670 mm

Overall height: 2,530 mm

... ceramics, crystals, etc. Up to two tool spindles mean faster processing and shorter cycle times. CAMPos: integrated post processing for CAD/CAM applications. Reduced setup time with integrated measuring probe for center ...

X travel: 600 mm

Y travel: 770 mm

Z travel: 810 mm

... production. The benefits at a glance Reduced machine width Maximum tool length Fast tool change Broad range of applications Modern machine design Expandable tool pockets in the ...

GROB-WERKE

X travel: 50 mm - 210 mm

Y travel: 80 mm - 150 mm

Z travel: 150 mm - 155 mm

... features: Direct machining from bar (turning or milling), 3 machining units working simultaneously at each station, multi-spindle turning and transfer machines in a single machining system. ...

Rotational speed: 15,000, 40,000 rpm

Power: 13.5, 18 kW

... Multistep machining system is a true productivity center! Thanks to its unique, unbeatable modularity and flexibility, ongoing production requirements can be accommodated at any time, with incomparable ...

X travel: 0 mm - 500 mm

Y travel: 0 mm - 400 mm

Z travel: 0 mm - 400 mm

The ultimate all-round vertical machining centre Fitted with a standard bed, the machines are the ultimate all-rounders, driving up productivity on a whole range of milling and drilling tasks requiring ...

X travel: 70 mm

Z travel: 85 mm

Rotational speed: 300 rpm - 400 rpm

... making masking possible. High Precision Machining Processes all polygon mirrors equipped in laser printers High Rigidity, High Stability Uses a high rigidity and high stability facilitating specialized ...

Shibaura Machine

X travel: 6,000 mm - 10,000 mm

Y travel: 3,750, 4,750, 5,750 mm

Z travel: 1,500, 1,750, 2,000 mm

... solutions, following particular needs of different industries such as aerospace components, power generation parts, high accuracy machining, molds, dies and design studios.

X travel: 1,320, 1,020 mm

Y travel: 610, 630 mm

Z travel: 610, 680 mm

... Bridgeport XR- Series machining centers are ideal for your operation. Bridgeport XR machines easily satisfy the most demanding production and precision component machining ...

X travel: 520 mm - 2,160 mm

Y travel: 400 mm - 762 mm

Z travel: 510, 650, 480, 625 mm

... capacities - there is definitely a DNM machine that meets your needs. Highlight Reliability Stability The largest machining area in its class. New DNM series machines are equipped with a larger table with ...

DN SOLUTIONS

X travel: 400 mm

Y travel: 400 mm

Z travel: 150 mm

... materials. ✅Advanced Ultrasonic Machining Technology Ultrasonic machining adds 16k~60kHz vibration to the rotating cutting tool, which effectively reduces cutting forces by over 30%. Rotary ultrasonic ...

Conprofe

X travel: 250 mm

Y travel: 250 mm

Z travel: 250 mm

... function) With ultrasonic function, MQL function optional High speed, high efficiency, high precision Compact structure, small size Applications: For machining hard-brittle materials(such as ceramic, ...

Conprofe

X travel: 500 mm

Y travel: 500 mm

Z travel: 500 mm

... simultaneous machining with RTCP Function ✅Excellent dynamic machining performance, high-precision, high-speed and high-efficiency machining ✅Full closed loop control ...

Conprofe

X travel: 2,000 mm - 20,000 mm

Y travel: 1,600 mm - 4,000 mm

Z travel: 1,000 mm - 2,000 mm

... equipped with 5 axes continuous interpolation as well as with “Index” type heads. VentorFast performs high speed machining and high accuracy processing of aluminum and steel, with proved successfull ...

X travel: 2,000 mm - 20,000 mm

Y travel: 1,600 mm - 4,000 mm

Z travel: 1,000 mm - 2,000 mm

VentorMaster is a 5-axis machining centre designed to obtain high torque needed to work on hard metals such as steel and titanium. This machines have a fixed table and mobile transversal bar which runs along the X axis ...

X travel: 800 mm

Y travel: 900 mm

Z travel: 650 mm

... four-linear-guideway design on Y axis performs high-rigidity and high-precision machining. Standard 32-tool magazine can couple with the 2nd tool magazine (opt.)–32T+32T large tool ...

X travel: 650 mm

Y travel: 800 mm

Z travel: 500 mm

... as well as highly precise 5-axis milling with positioning. The grey cast iron base, thermo-symmetrical set-up and the fact that only 2 axes on the tool side are used for cutting, result in maximum rigidity ...

FEHLMANN

X travel: 650 mm

Y travel: 800 mm

Z travel: 500 mm

Highest level of precision and dynamics This 3-axis machining center with a fixed table offers a generously-sized clamping area of 870 x 760 mm. Workpieces up to 1000 kg can be machined ...

FEHLMANN

X travel: 500 mm

Y travel: 650 mm

Z travel: 420 mm

... as well as highly precise 5-axis milling with positioning. The grey cast iron base, thermo-symmetrical set-up and the fact that only 2 axes on the tool side are used for cutting, result in maximum rigidity ...

FEHLMANN

X travel: 4,000, 5,000, 2,000, 3,000, 6,000 mm

Y travel: 1,500 mm - 4,000 mm

Z travel: 1,500, 2,000, 2,500, 3,000 mm

... customers. This planer type machining center can successfully carry out boring and milling works. It is characterised by its symmetrical design with a centred headstock on the column, ...

X travel: 1,000 mm

Y travel: 1,000 mm

Z travel: 750 mm

... designing a precise and high-performance machining centre. The C 52 is the successor of the extremely successful C 50. The C 52 machining centre: A flexible all-rounder with a large working area and ...

X travel: 1,050 mm

Y travel: 900 mm

Z travel: 600 mm

... . The C 650 has an integrated tool magazine for 42 tools. The control panel of the C 650 is also designed to swivel easily to the magazine loading location, so the operator can enter the tool data directly ...

X travel: 2,400 mm - 9,500 mm

Y travel: 2,500 mm - 42,000 mm

Z travel: 1,200 mm - 4,000 mm

... addressed to industries requiring a large work envelop along with a high degree of precision such as machining moulds for the automotive, wind energy and marine industry Heavy duty ...

Multiax International CNC srl

X travel: 1,800 mm - 3,800 mm

Y travel: 1,800 mm - 16,000 mm

Z travel: 250 mm - 1,200 mm

... different versions with different designs and weights for several applications: from nesting of aluminum stacked sheets to machining of long components. The structure of the N SERIES is also used to configure highly customized ...

Multiax International CNC srl

X travel: 4,000, 3,000 mm

Y travel: 3,600, 2,600 mm

Z travel: 400 mm

... , to deliver long-life reliability and consistent high precision. B SERIES specifically feature extra rigid weldments, with opposing slide ways and extra reinforced cross beams, for total precision across ...

Multiax International CNC srl

X travel: 4,200 mm

Y travel: 2,500 mm

Z travel: 1,000 mm

• Mitsubishi M80A controller with mfr. warranty • 15" LCD screen control panel for all models • 20 bar CTS (Coolant Through Spindle) • Air gun and coolant gun • Rigid tapping • M30 automatic power off • Full moulding package in ...

X travel: 3,300 mm

Y travel: 250 mm

Z travel: 200 mm

Machining center with moving column and vertical spindle with 4 axis controlled by CNC including rotation of the clamp base which allows any angle ranging from -90 ° to + 90 ° in automatic working cycle. -Motor ...

... areas where sawdusts and wastes fall provides a long life. • - Standard model has sawdust conveyor, 10 clamps and tool chuck with 16 tool holding capacity. Number of clamps can be increased optionally. • ...

X travel: 4,385 mm

Y travel: 1,250 mm

Z travel: 590 mm

• - Standard model has 6 clamps and tool chuck with 8 tool holding capacity. • - In order to ensure continuous precision, stress relieving method is applied in cast and welded pieces. • ...

X travel: 4,385 mm

Y travel: 1,250 mm

Z travel: 590 mm

• - Standard model has 6 clamps and tool chuck with 8 tool holding capacity. • - In order to ensure continuous precision, stress relieving method is applied in cast and welded pieces. • ...

X travel: 1,000, 600, 800 mm

Y travel: 600, 700 mm

Z travel: 480, 380 mm

... absolutely eliminate overhanging problems, providing the best Machining & Engraving Solutions. Transmission system Extra Heavy Duty Roller Type Linear Ways on X-Y-Z axes; Class C3 high precision ...

Taiwan Winnerstech Machinery Co., Ltd.

X travel: 850, 1,000 mm

Y travel: 560 mm

Z travel: 560 mm

... workpiece structure all contribute to the ability for heavy duty machining. High rigidity high precision. The enhanced ribs in major construction parts provide the super rigidity for ...

Taiwan Winnerstech Machinery Co., Ltd.

X travel: 1,800, 1,900 mm

Y travel: 900 mm

Z travel: 800 mm

... adopt heavy duty linear ways for E type machine but Z axis boxway which has been precisely ground by handcraft ; Not only to guarantee the smoothly movement on X-Y axes, but also not losing any rigidity consideration ...

Taiwan Winnerstech Machinery Co., Ltd.

X travel: 2,000, 5,000, 2,500, 3,000 mm

Y travel: 1,300, 3,000, 1,500, 2,000 mm

Z travel: 1,100 mm

The heavy-duty 5 axis CNC machining center can realize multiple complex and heavy-duty processes. It adopts the moving gantry and fixed worktable structure, ensuring great flexibility ...

X travel: 2,400 mm

Y travel: 1,200 mm

Z travel: 1,000 mm

This 5 axis CNC milling machine has the advantages of fast machining speed, high machining efficiency, and high machining accuracy. The work piece only needs to be clamped ...

X travel: 600 mm

Y travel: 500 mm

Z travel: 250 mm

... a CNC milling machine that can be used for both engraving and milling with the features of high precision and high efficiency. And it is mainly used for the processing of all kinds of ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- DMG MORI precision machining centers

- Haas precision machining centers

- Breton precision machining centers

- EMCO precision machining centers

- Knuth Machine Tools precision machining centers

- Conprofe precision machining centers

- FEHLMANN precision machining centers

- HERMLE precision machining centers

- Takumi precision machining centers

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining