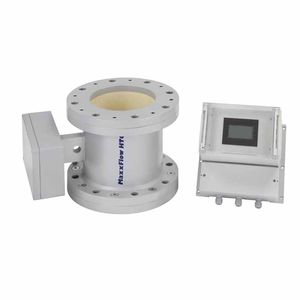

Mass flow meter SolidFlow 2.0microwavefor bulk materialsin-line

Add to favorites

Compare this product

Characteristics

- Technology

- mass, microwave

- Fluid

- for bulk materials

- Installation

- in-line, flush-mount

- Applications

- for the pharmaceutical industry, for the food industry, for harsh environments

- Process temperature

200 °C, 900 °C

(392 °F, 1,652 °F)- Process pressure

1 bar, 10 bar

(14.5 psi, 145.04 psi)

Description

Continuous mass flow measurement of all types of dust, powder and granules in free fall and pneumatic conveying

Microwave sensor for on-line mass

flow measurement of solids up to

20 t/h.

Used in pneumatic leanphase conveying or vertical freefall after mechanical feeders.

• easy assembly via weld-on socket

• for almost all types of dusts, powders, granules

• atest technology with active roping compensation

• suitable for nearly all pipe diameters

FEATURES & BENEFITS

• Simple retrofitting using a welding socket

• ATEX-certified

• Almost all types of dust, powder and granules can be measured

• No installations in the material stream

• Measuring principle: Microwave

• Online flow metering

• Throughput measuring flowrates up to 20 t/h

• Active roping compensation for highest reliability

• Wear-resistant

MAIN APPLICATIONS

• Biomass

• Cement

• Chemistry

• Coal plant

• Coating

• Food

• Incineration

• Minerals

• Wood

• Lime plant

• Energy

• Gypsum

• Power plant

• Foundry

Using:

SolidFlow 2.0 is a sensor especially developed for measuring the flow rate of solids conveyed in metallic ducts.

It has successfully been tested for online-measuring of:

• all types of dust, powder and granulates

• grain size between 1 nm and 1 cm

• pneumatically conveyed materials or

• in free fall after mechanical conveying systems

• SolidFlow is wear-resistant and the commissioning is very easy.

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Flowmeter

- Level probe

- Gas flowmeter

- Stainless steel flowmeter

- Waterproof flowmeter

- Industrial flowmeter

- Analog level probe

- In-line flowmeter

- Precision flowmeter

- Compact flowmeter

- Mass flowmeter

- DC flowmeter

- Digital flowmeter

- Flowmeter with display

- RS485 flowmeter

- Leakage detector

- IP65 flowmeter

- Flange flowmeter

- Storage tank level probe

- Explosion-proof flowmeter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.