- Machine-tools

- Machining Center

- 3-axis machining center

- Toyoda Machine Works

- Products

- Catalogs

- News & Trends

- Exhibitions

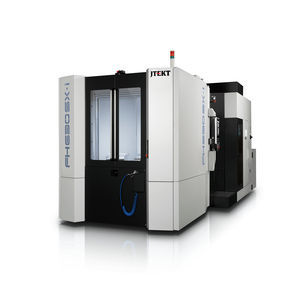

3-axis CNC machining center FH5000S-ihorizontalCAT4060 tools

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- horizontal

- Spindle mount

- CAT40

- Number of tool stations

- 60 tools

- Other characteristics

- high-speed, high-performance, direct-drive, high-rigidity, high-precision

- X travel

800 mm

(31 in)- Y travel

800 mm

(31 in)- Z travel

880 mm

(35 in)- Rotational speed

15,000 rpm

(94,248 rad.min-1)- Power

50 W

(0.07 hp)- Workpiece max height

1,100 mm

(43 in)- Work feed X-axis

60,000 mm/min

(39 in/s)- Work feed Y-axis

60,000 mm/min

(39 in/s)- Work feed Z-axis

60,000 mm/min

(39 in/s)- Table load capacity

1,000 kg

(2,205 lb)- Tool weight (max)

8 kg

(17.6 lb)- Overall length

2,980 mm

(117.3 in)- Overall width

4,850 mm

(190.9 in)- Overall height

2,809 mm

(110.6 in)

Description

Industry-leading high-precision performance optimized for speed, rigidity and reliability.

Designed to achieve remarkable speed and production reliability, JTEKT’s FH5000 Series meets the growing demand for high metal removal rates, short cycle times and superior surface finishes. It features standard 60-tool ATC capacity, along with a 15,000 RPM, 50 HP (37 kW), 303 Nm (223 ft-lbs.) high acceleration spindle. Equipped with a direct drive B-axis table featuring an index time (90°) of 0.7 seconds - the FH5000’s spindle design, preload system and high torque features allow manufacturers to take advantage of more aggressive, high-volume machining in a compact footprint.

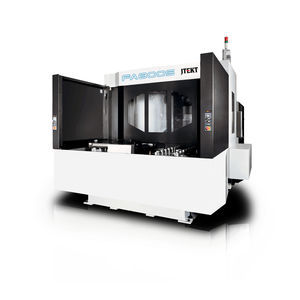

Other Toyoda Machine Works products

HORIZONTAL MACHINING CENTERS

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- 3-axis CNC machining center

- CNC turning center

- Precision CNC machining center

- 2-axis turning center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Drilling machine

- Cutting CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- Turning center with turret

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.